Contact

, Trävetenskap och träteknologi

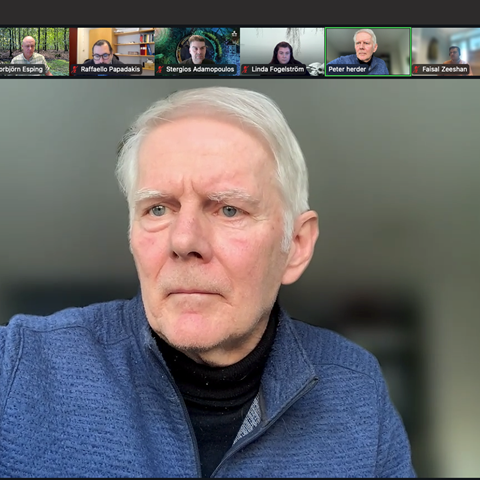

“Address the needs in the industry”. That was the key message from Dr. Peter Herder, an expert with 25 years of experience bio-adhesive development, during a recent BioGlue-Centre webinar.

Dr. Herder, former R&D manager at Akzo Nobel and now part of IKEA’s task force on bio-adhesives, emphasized the significant environmental impact of traditional adhesives.

“We are facing a dramatic change in the climate, and we need to take action,” he stated, beliving that developing sustainable adhesives will not only benefit the environment but also propel industrial progress.

There are multiple approaches to making adhesives more sustainable. One potential route is replacing fossil-based carbon with bio-based carbon, such as producing bio-formaldehyde. However, the energy required for this process poses a challenge.

“When you go for green carbons, you might actually increase the carbon footprint because the processes are still reliant on fossil-based energy,” Herder explained.

Additionally, formaldehyde—regardless of whether it is bio-based or fossil-based—remains associated with health risks.

“I wouldn’t invest too many resources in bio-formaldehyde. It might offer a slightly improved carbon footprint, but at the end of the day, formaldehyde has a poor reputation,” he noted.

Bio-based adhesives can be derived from a range of materials, including proteins, starches, and wood components such as lignin, hemicellulose, cellulose, and tannins. However, Herder stressed that for these alternatives to be viable, they must be available in large quantities, at stable quality and pricing.

“We need to connect research results to real-world applications. Otherwise, we won’t see bio-based adhesives making it to the market,” he cautioned.

Lignin, already widely used in bio-adhesives, holds significant potential but comes with challenges.

“It’s not well-defined. Lignin varies significantly depending on its source and extraction method,” Herder explained. “To make it more uniform, you need costly refining processes, which can offset its advantages.”

When asked which bio-based solution he sees as most promising, Herder pointed to starch.

“I think there are many opportunities in working with starch. Modifying starch presents an interesting avenue for adhesive systems,” he concluded.